MANUFACTURER’S REPRESENTATIVE AGENCY FOR THE O.E.M. MARKET

Contact Us Today!

Call: 770-317-0008

Email: tom@seesales.com

1402 S Snapper Ln.

Fernandina Beach, FL 32034

About Southeast Engineered Sales, Inc.

Southeast Engineered Sales, Inc. strengthens the partnerships between principles and customers. Our principles cover a wide range of engineered products for the O.E.M. Market. Our large customer base includes Outdoor Power Equipment, Appliance, Automotive, ATV’s, Furniture and HVAC.

Southeast Engineered Sales is the product of the merger of Gateway Sales and Low Associates, in January 2002. This merger offers principals and customers 50 years of experience to the seven Southeastern states. Of the five principals, one has been with us for 50 years, while the others have been associated with us for more than 20 years.

We specialize in steel tube assemblies and fabrications, stampings, wire fabrications, laser cutting services and machined castings. Hardware items include automotive fasteners, rivets, specialty washers, springs, rivnuts, PEM standards and specials of all kinds.

770-317-0008 • tom@seesales.com • 1402 S Snapper Ln. – Fernandina Beach, FL 32034

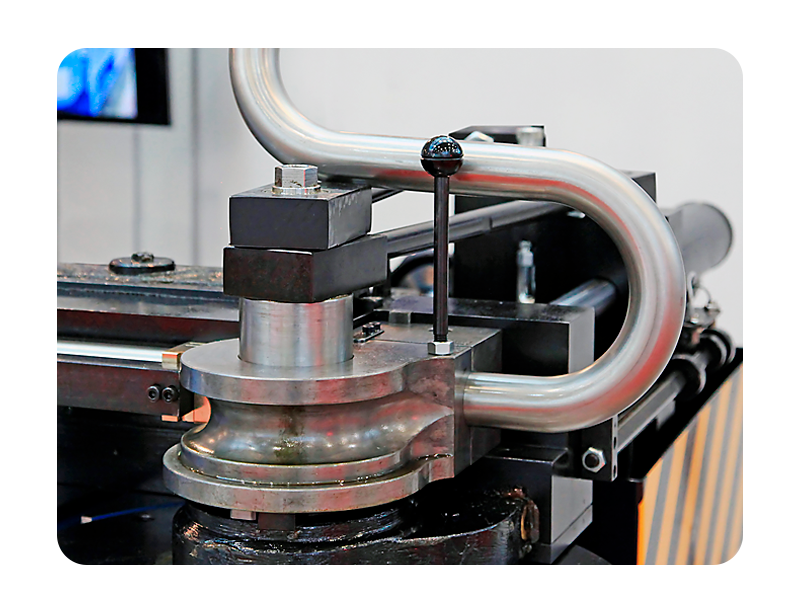

Fabricators of Metal Tubular Parts & Assemblies

Bohn and Dawson is one of the largest contract tubing fabricators of its kind in North America. Bohn and Dawson is an ISO 9001:2015 certified facility. We have 50+ tube benders in house, 100+ punch presses, 6 robotic arc welding systems, 2 laser tube processing system and a robotic plasma cutting/profiling system. We have 3D CAD systems and in-house tool and die design/build/maintenance that covers nearly all of Bohn and Dawson’s needs. Bohn and Dawson is geared to support high volume tube fabrication for today’s demanding, dynamic manufacturing environment and have the delivery and quality awards to prove it.

- Incorporated in 1946

- Engineering Based Management

- Multiple Markets Served including Automotive, Outdoor Power Equipment, Agriculture and Appliance

- Over 250,000 square feet of manufacturing and warehousing in the United States

- Virtual control of 12 tube mills

- 25 separate JIT programs running simultaneously

- Components shipped to your locations made to your specification with or without coatings

- Highly professional staff providing an engineering-based solution to serve you

Supply Chain Management

S.W. Anderson is a stocking distributor and engineering representative for specialty fasteners, standard fasteners and other OEM components. Our full line of products and quality brands simplifies your ordering process and keeps your business running smoothly.

Your product requirements, like your projects, are often unique. Our customizable supply chain services are designed to fit your specific needs and streamline your receiving and inventory management processes, getting you to production faster.

- Custom packaging, labels, part numbers and descriptions

- Kitting

- Reusable delivery container programs

- Dock-to-stock delivery

- Certifications Include: ISO 9001:2015, DFARS & RoHS

- VMI – Vendor Managed Inventory Capable

- Lines offered include Atlas, PEM, Stanley and Huck